Description

For sale is a New Build Trailer Mounted Coiled Tubing Unit.

1.0 DESCRIPTION

COILED TUBING UNIT CONSISTS OF THE FOLLOWING COMPONENTS TRAILER WITH CABIN, HOSE REEL, 4.06 10K BOP & STRIPPER, POWER PACK, COILED TUBING REEL AND INJECTOR.

2.0 POWER PACK

2.1 ENGINE SERIES 60 REMANUFACTURED WITH 18 MONTH WARRANTY

2.1.1 UNIT TO BE PAINTED CUSTOMER REQUIRED COLORS.

2.2 HYDRAULICS

2.2.1 OPEN LOOP LOAD SENCE SYSTEM

2.2.2 GEARBOX TO DRIVE FOLLOWING PUMPS.

2.2.2.1 AXIAL PISTON PUMP FOR INJECTOR DRIVE. 160 GPM NOMINAL.

2.2.2.2 VANE PUMPS FOR ALL OTHER FUNCTIONS. FUNCTIONS TO INCLUDE; TUBING REEL POWER, LEVEL WIND OVERRIDE, INJECTOR CHAIN TENSION & TRACTION, LEVELWIND LIFT CYLINDER, HOSE REEL SUPPLIES, CONTROL CABIN LIFT CYLINDERS, BOP, AND STRIPPER CONTROLS.

2.2.2.3 AUXILIARY PUMP DEDICATED TO CLOSED LOOP FLUSHING.

2.2.2.4 PUMPS TO HAVE DUMP VALVES FOR START-UP AT NO LOAD.

2.2.3 HYDRAULIC RESERVOIR CAPACITY 140 GALLON WITH SIGHT GAUGE.

2.2.3.1 TANK TO HAVE FILTERED FILL CONNECTION.

2.2.4 AIR TO OIL HEAT EXCHANGER.

2.2.5 4-10 GAL. ACCUMULATORS FOR BOP CIRCUIT.

2.2.6 ALL NECESSARY HYDRAULIC VALVES, GAUGES, HOSES, FILTERS, AND PIPING.

2.2.6.1 FILTERS TO HAVE BY PASS INDICATORS / RESTRICTION GAUGES AT ALL FILTERS.

3.0 CONTROL CABIN

3.1 TELESCOPING CONTROL CABIN, LIFT MECHANISM TO BE FOUR-POST STYLE, NOT SCISSOR.

3.2 ONE (1) SLIDING TYPE WINDOW, RAIN GUTTER. FRONT WINDOW WITH RAIN GUTTER. WINDSHIELD IS ¼” SAFETY GLASS. LARGE SLIDING TYPE WINDOWS ON SIDE WALLS. LADDERS TO GROUND TO HAVE HANDRAILS

3.2.1 TWO (2) EXTERIOR FLOOD LIGHTS TO BE INSTALLED ON FRONT OF CABIN, TWO (2) INTERIOR FLUORESCENT LIGHTS AND TWO (2) MAP LIGHTS INSTALLED ABOVE CONTROL CONSOLE, ONE (1) FLUORESCENT LIGHT INSTALLED AT REAR OF CABIN AND ONE (1) EXTERIOR FLOOD LIGHT MOUNTED ABOVE PORCH.

3.2.2 ONE (1) PADDED BENCH SEAT, 18” WIDE, AGAINST SIDE WALLS.

3.2.3 CABIN TO BE INSULATED.

3.2.4 AIR HORN

3.2.5 AIR CONDITIONER/HEATER.

3.3 BULKHEAD PANEL FOR HOSE CONNECTION.

3.4 “U” SHAPE DESIGN CONTROL CONSOLE CONTAINS THE FOLLOWING:

3.4.1 ONE (1) 4-BANK VALVE, FOR BOP CONTROL, WITH LOCK-OUT LATCH. TWO HANDLES NEXT TO ACTIVATOR TO BE PAINTED RED. ALL OTHER HANDLES TO BE YELLOW.

3.4.2 BOP PRESSURE GAUGE.

3.4.3 AIR REGULATOR VALVE, PRESSURE VALVE, BLEED VALVE AND GAUGES TO OPERATE DUAL ACTING STRIPPER. HYDRAULIC SUPPLY FOR STRIPPER IS AIR-OVER-PUMP WITH MANUAL OVERRIDE.

3.4.4 WEIGHT INDICATORS FOR INJECTOR, 60,000 LBS. TO BE MOUNTED CENTER OF PANEL.

3.4.5 PRESSURE REGULATOR VALVE WITH ISOLATION AND GAUGES FOR INJECTION TRACTION CIRCUITS.

3.4.6 CONTROL VALVE INJECTOR SPEED AND DIRECTION, WITH 0-600 PSI GAUGE.

3.4.7 SELECTOR VALVE FOR TWO SPEED CONTROL AND INJECTOR BRAKE.

3.4.8 GAUGE FOR INJECTOR BRAKE PRESSURE.

3.4.9 PRESSURE CONTROL VALVE FOR SETTING INJECTOR PULL CONTROL.

3.4.10 NEEDLE VALVES FOR INJECTOR CHAIN AND REEL TUBING OILER

3.4.11 HYDRAULIC PRESSURE GAUGE (4”) FOR INJECTOR PULL.

3.4.12 VALVE FOR REEL CONTROL AND 2-BANK FOR LEVELWIND RAISE AND LOWER, AND LEVELWIND OVERRIDE.

3.4.13 RELIEF VALVE FOR REEL TENSION CONTROL.

3.4.14 PRESSURE GAUGE FOR REEL TENSION.

3.4.15 VALVE FOR REEL BRAKE.

3.4.16 TWO (2) 6”, 15,000 PSI PRESSURE GAUGES FOR WELLHEAD PRESSURE AND CIRCULATING PRESSURE TO BE MOUNTED TO RIGHT OF WEIGHT INDICATOR. BOTH GAUGES 4:1 DE-BOOSTED.

3.4.17 ELECTRIC CONTROLS FOR ENGINE SPEED, KILL AND EMERGENCY KILL.

3.4.18 PRESSURE GAUGE FOR INJECTOR OUTSIDE CHAIN TENSION CONTROL.

3.4.19 FULL ENGINE INSTRUMENTS INCLUDING TACHOMETER (DIGITAL), AIR PRESSURE GAUGE.

3.4.20 CUSTOMER’S LOGO ENGRAVED ON CONTROL PANEL ONLY.

3.4.21 VALVE FOR SLOW SPEED CONTROL.

3.4.22 INJECTOR INSIDE TRACTION PRESSURE DRAIN VALVE.

4.0 TUBING REEL

4.1 MOUNTED ON FOUR AXLE TRAILER.

4.2 REEL DRUM DESIGN WITH HEAVY CORE TO SHAFT STRUCTURE. REEL CAPACITY IS 25,000’ (7500 METERS) OF1-1/ 2” COILED TUBING. FLANGES HAVE EXPANDED METAL PANELS. REEL DRUM IS LOCKED IN POSITION BY MEANS OF NYLON STRAPS WITH EIGHT LOCKING POSITIONS AROUND THE CIRCUMFERENCE OF THE FLANGE.

4.3 TWO-POINT LIFT SPREADER BAR ARRANGEMENT FOR LIFTING ENTIRE LOADED REEL ASSEMBLY.

4.4 REEL DRIVE AND LINE TENSIONING SYSTEM WITH PLANETARY DRIVE WITH INTERNAL BRAKE. SYSTEM CAPABLE OF SPOOLING TUBING AT 2,500 PSI HYDRAULIC PRESSURE OR LESS. MOTOR CASE DRAIN AND BRAKE PROTECTED BY POP-OFF RELIEF VALVES. CROSS LINE RELIEF VALVES IN MOTOR.

4.5 DIAMOND LEAD SCREW (W/ STEEL PAWL) LEVEL WIND SYSTEM WITH MECHANICAL DRIVE AND REMOTELY-OPERATED HYDRAULIC OVERRIDE. LEVELWIND ARM HYDRAULICALLY RAISED TO WORKING POSITION. DUAL-BAR CROSS-TRACK DESIGN.

4.6 TUBING COUNTER WITH VERTICAL SLIDE MOUNT TO COMPENSATE FOR TUBING PAY-OFF ANGLE. COUNTER READS IN FEET OR METERS AND IS SIZED FOR 1-1/2” TUBING.

4.7 10,000 PSI CIRCULATING SWIVEL, 1.5” BORE, SUITABLE FOR BOTH H2S AND NON-H2S SERVICE. FLANGE MOUNTED WITH COMPRESSION FACE SEAL.

4.8 NON-H2S EXTERNAL PLUMBING MANIFOLD USING INTEGRAL 1502 TYPE FITTINGS RATED AT 15,000 PSI. DUAL INLET CONNECTIONS (ONE EACH SIDE OF SWIVEL WITH 2X1 PLUG VALVE) AND 2X2 SHUTOFF VALVE BETWEEN SWIVEL AND INLETS. A 4:1 DE BOOSTER, WITH 1502 CONNECTION, IS PROVIDED FOR MONITORING CIRCULATING PRESSURE.

4.9 NON-H2S INTERNAL PLUMBING MANIFOLD USING INTEGRAL 1502 TYPE FITTINGS RATED AT 15,000 PSI.

4.10 HYDRAULIC AND PNEUMATIC CONNECTIONS MADE AT BULKHEAD PANEL. QUICK DISCONNECTS.

4.11 ALL CHAINS HAVE REMOVABLE PROTECTIVE GUARDS. LEVELWIND CHAIN GUARD HAS HINGED COVER FOR QUICK CHANGE OUT OF SPROCKETS AND CLUTCH ADJUSTMENTS.

4.12 GREASE FITTING BULKHEAD PANEL. CHAINS UNPAINTED AND GREASED PRIOR TO SHIPMENT.

4.13 HYDRAULICS AND GREASE LINES USE STANDARD CLIMATE RATED HOSES.

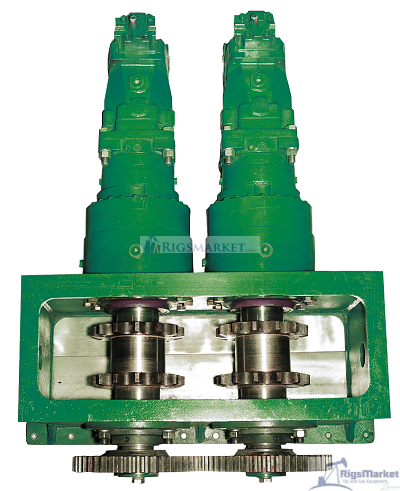

5.0 INJECTOR HEAD EVOLUTION 80K

THE 80K IS DESIGNED FOR HANDLING COILED TUBING SIZES FROM 1.25” OD THROUGH 2-3/8” OD. IT IS DESIGNED FOR OPERATION WITH BOTH OPEN LOOP AND CLOSED LOOP HYDRAULIC SYSTEMS. PULL CAPACITIES ARE AS FOLLOWS:

40,000 LBS. PULL CAPACITY @ 3000 PSI

80,000 LBS. PULL CAPACITY @ 4800 PSI

MAXIMUM SPEED 165 FEET PER MINUTE

ALL STRUCTURES AND ANCILLARY SYSTEMS ARE DESIGNED TO THE 90,000 LB. LOAD LIMIT. SNUBBING CAPACITY IS 40,000 LB. WITH INJECTOR IN LOW RANGE. THE CAPACITIES PROVIDED IN THE FOLLOWING ARE BASED ON CLOSED LOOP HYDRAULIC SYSTEM OPERATION.

5.1 THE DRIVE SPROCKETS ARE SPLINED TO DRIVE SHAFTS FOR PRECISE ALIGNMENT AND STRENGTH. DRIVE COMPONENTS ARE NICKEL PLATED FOR CORROSION RESISTANCE.

5.2 INJECTOR POWER TO BE SUPPLIED FROM DUAL HIGH SPEED / HIGH PRESSURE BENT AXIS VARIABLE DISPLACEMENT PISTON MOTOR.

5.3 A MODULAR BRAKE IS MOUNTED BETWEEN THE MOTOR AND GEARBOX AND IS A SPRING APPLIED / PRESSURE RELEASED. THE BRAKE IS MANUALLY CONTROLLED FROM THE CABIN.

5.4 THE HYDRAULIC DRIVE MOTORS IS HARD PLUMBING DIRECTLY TO TWO COUNTERBALANCE SAFETY VALVES TO PREVENT LOSS OF CONTROL IF POWER FAILURE OCCURS.

5.5 EACH HYDRAULIC LINE SUPPLYING FLOW TO THE DRIVE MOTOR IS PROTECTED WITH HIGH PRESSURE IN-LINE FILTER MOUNTED BETWEEN THE QUICK-DISCONNECT AND COUNTERBALANCE VALVES. THE FILTERS INCORPORATE A VISUAL CONDITION INDICATOR.

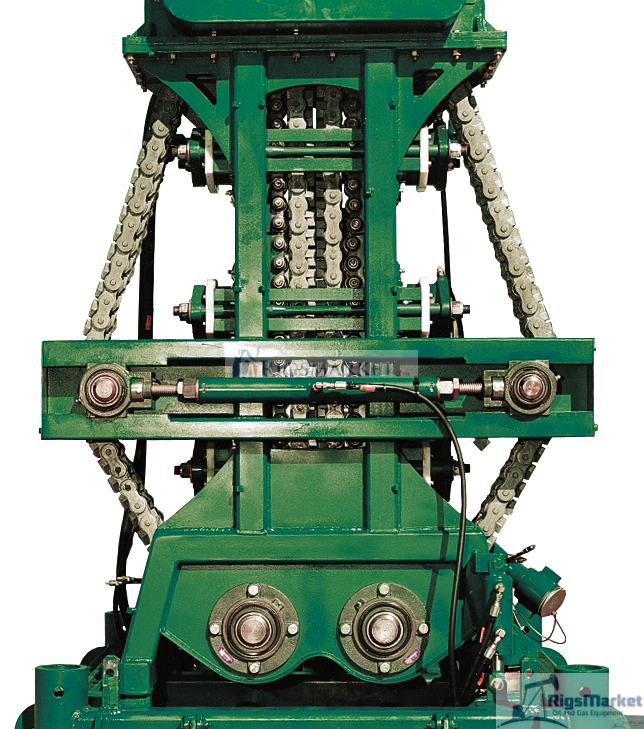

5.6 INJECTOR SUPPLIED WITH 1-1/2” CHAINS

5.7 TUBING TRACTION SYSTEM INCORPORATES THREE (3) INDEPENDENT SETS OF TWO (2) ROD TYPE HYDRAULIC CYLINDERS WITH ACCUMULATORS TO APPLY A BALANCED LOAD. HYDRAULIC CYLINDERS WITH ACCUMULATORS TO APPLY A BALANCED LOAD. TUBING TRACTION IS APPLIED TO THE CHAIN SYSTEM OVER 42” OF CONTACT LENGTH THROUGH A PAIR ROLLER BEARING HOLDERS. THE SYSTEM IS DESIGNED FOR SELF-CENTERING FOR UNIFORM GRIPPER AND TUBING LOADING. TRACTION SYSTEM IS REMOTE CONTROLLED FROM THE OPERATORS CONSOLE.

5.8 CHAIN LOOP TENSION PROVIDED BY HYDRAULIC CYLINDERS WITH ACCUMULATORS, REMOTE CONTROLLED FROM OPERATORS CABIN.

5.9 ADJUSTABLE POSITION, 72” TUBING GUIDE ARCH, MOUNT DESIGNED TO FOLD DOWN FOR STORAGE OR REMOVABLE.

5.10 DUAL SINGLE ACTING LOAD CELLS TO PROVIDE DIRECT PIPE HEAVY AND PIPE LIGHT WEIGHT INDICATION

WEIGHT INDICATION (PIPE HEAVY): 80,000 LBS.

WEIGHT INDICATION (PIPE LIGHT): 40,000 LBS.

5.11 FLANGE MOUNT FOR STRIPPER IS PROVIDED ON THE INJECTOR BASE. STRIPPER MOUNTING CONFIGURATION TO BE FOR 3.06” SIDE DOOR STRIPPER.

5.12 COMPLETE INJECTOR ASSEMBLY MOUNTED ON STEEL BASE. COUPLING PANEL INSTALLED AT BOTTOM FRONT OF INJECTOR.

5.13 OUTER CRASH FRAME HAS A 4-POINT LIFT SLING AND MOTOR GUARDS.

5.14 ONE (1) SET TELESCOPING SUPPORT LEGS WITH 8” SCREW ADJUSTMENT. IN ADDITION, A SET OF SHORT FIXED LEGS FOR SUPPORTING THE INJECTOR WITH STRIPPER MOUNTED IS PROVIDED.

5.15 CHAIN LUBE RESERVOIR TO BE MOUNTED ON TRAILER.

5.16 DE-BOOSTER FOR WELLHEAD PRESSURE.

6.0 INJECTOR POWER HOSE REEL / HOSES

6.1 HYDRAULICALLY POWERED HOSE REEL TO ACCOMMODATE TWO (2) 1-1/4” x 100’ LONG INJECTOR POWER HOSES WITH CONNECTIONS.

6.2 INJECTOR CONTROL HOSES ARE 100’ AND WRAPPED FIGURE EIGHT STYLE AND STORED ON THE TRAILER.

6.2 BOP CONTROL HOSES ARE 100’ AND WRAPPED FIGURE EIGHT STYLE AND STORED ON CRANE TRAILER.

7 GENERAL

7.1 FOUR AXLE TRAILER.

7.2 MAXIMUM WIDTH OF 8’6”.

7.3 FOUR REAR AXLES, 25,000 LBS. EACH MAXIMUM.

7.4 TIRE SIZE OF 245/75R X 22.5

7.5 MOUNTING BRACKETS FOR ALL COMPONENTS INCLUDING INJECTOR, REEL, CABIN, AND POWER PACK.

7.6 TOOLBOX, INSTALLED.

7.7 UNDER DECK MOUNTED HOSE PACKAGE FOR INTERCONNECTION OF CABIN, REEL AND CONTROL HOSES.

7.8 MUD FLAPS.

7.9 STEPS WELDED UNDER SIDE OF TRAILER TO ACCESS REEL ON BOTH SIDES.

7.10 HANDRAILS AROUND REAR SECTION OF TRAILER FROM REEL BACK.

8.0 ADDITIONAL

8.1 ALL HOSE BUNDLES TO BE PROTECTED WITH HOSE SLEEVES. ALL CONNECTIONS TO BE AEROQUIP.

8.2 COMPLETE UNIT SANDBLASTED, PRIMED, AND PAINTED TO CUSTOMER SPECIFICATIONS.

8.3 COMPLETE UNIT ASSEMBLED AND TESTED FOR CUSTOMER ACCEPTANCE AT xyz FACILITY.

8.4 THREE (3) OPERATION MANUALS SUPPLIED WITH EACH UNIT.

8.5 ALL CASE DRAINS TO HAVE POP-OFFS FOR CASE PROTECTION.

9.0 BOP & STRIPPER

9.1 4.06 BORE 10K WORKING 15K TEST PRESSURE QUAD BOP.

9.2 4.06 BORE 10K WORKING 15K TEST PRESSURE SIDE DOOR STRIPPER.

9.3 – ID 4.06″

Overall Height 49.8″

Made up Height 46.1″

Length 65.4″

Weight 3959 lb

Working Pressure 10000 psi

Test Pressure 15000 psi

Top Connection BX169 Studded

Bottom Connection BX169 Studded

1st Set of Ram/Seal Dressed for Shear Blinds

2nd Set of Ram/Seal Dressed for 1.75″ Pipe Seals

3rd Set of Ram/Seal Dressed for 1.75″ Pipe Slips

4th Set of Ram/Seal Dressed for 1.75″ AS REQUESTED

Equalizing Ports: Above to Below Each Ram Set

Bleed Off Ports: 1/2″ NPT above each ram set

Pump in Port: 1 x BX152 Side Studded Between 1st

and 2nd Ram

Quick Lock Hydraulic Actuators

Includes Top and Bottom Aluminum Thread Protectors

H2S Rated – NACE MR-0175 Specification

Hydraulic Fitting: CT

Material and Pressure Test Certification